JMC Pressure Roller Units are mainly developed for use in the continuous furnace of Sintering and

Palletising plants. These ready to mount units are also suitable for all application where heavy loads

are to be accommodated and the direction of rotation is frequently reversed.

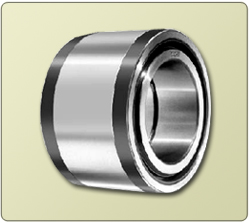

JMC Pressure Roller Units are basically double row full complement Cylindrical Roller Bearing. The

very thick walled outer ring has three integral flanges. The highly wear - resistant outside diameter

surface is cylindrical, being relieved towards the form of a chamfer.

The Inner ring is in two halves, each of which has an integral flange, which is designed to enable the units to carry heavy axial loads in addition to radials. |

|